2021 FDA Science Forum

The Effects of Formulation Factors and Actuator Design on Mometasone Furoate Metered Dose Inhaler In Vitro Aerosolization Performance

- Authors:

- Center:

-

Contributing OfficeCenter for Drug Evaluation and Research

Abstract

Introduction

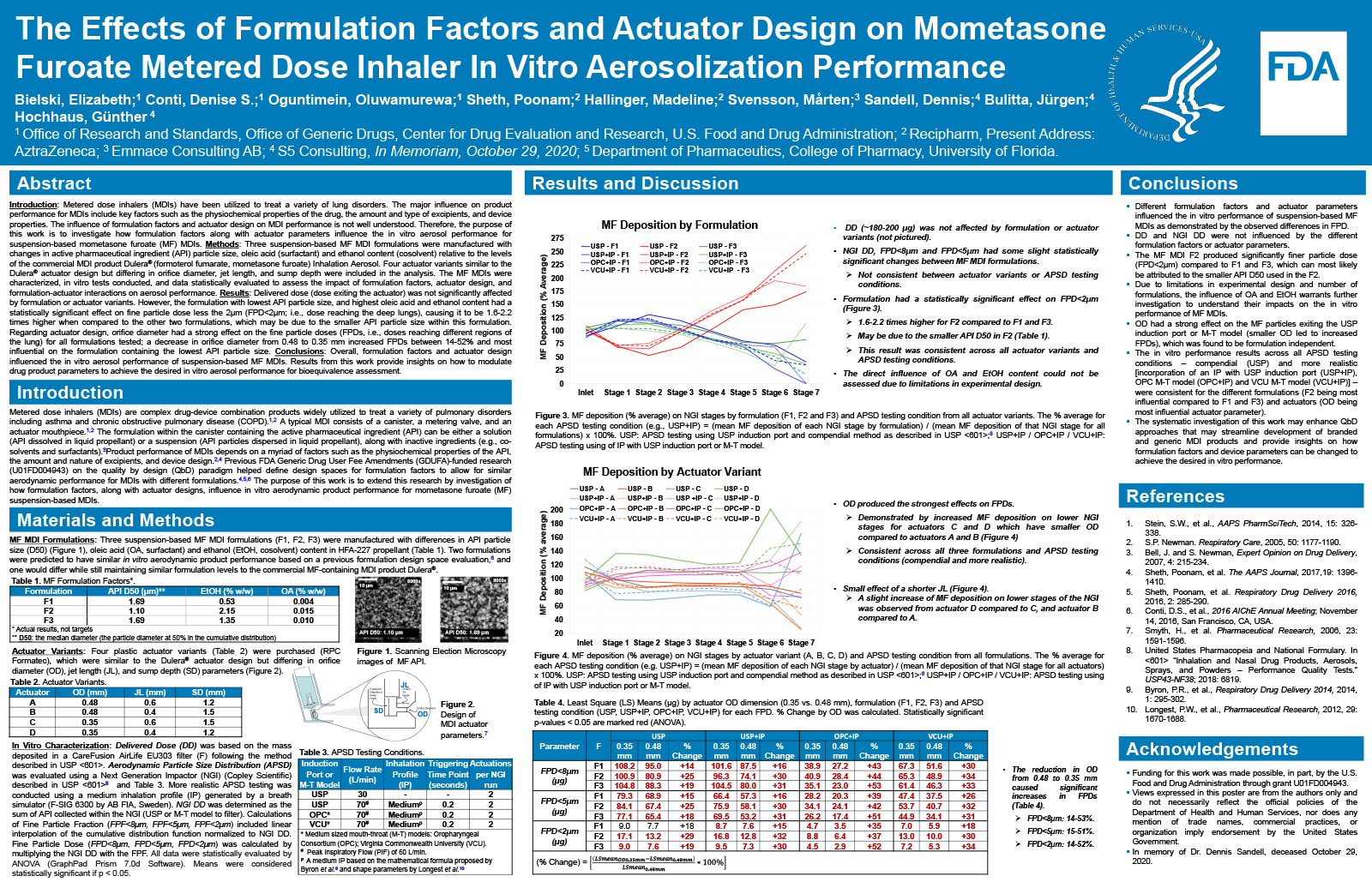

Metered dose inhalers (MDIs) have been utilized to treat a variety of lung disorders. The major influence on product performance for MDIs include key factors such as the physiochemical properties of the drug, the amount and type of excipients, and device properties. The influence of formulation factors and actuator design on MDI performance is not well understood. Therefore, the purpose of this work is to investigate how formulation factors along with actuator parameters influence the in vitro aerosol performance for suspension-based mometasone furoate (MF) MDIs.

Methods

Three suspension-based MF MDI formulations were manufactured with changes in active pharmaceutical ingredient (API) particle size, oleic acid (surfactant) and ethanol content (cosolvent) relative to the levels of the commercial MDI product Dulera® (formoterol fumarate, mometasone furoate) Inhalation Aerosol. Four actuator variants similar to the Dulera® actuator design but differing in orifice diameter, jet length, and sump depth were included in the analysis. The MF MDIs were characterized, in vitro tests conducted, and data statistically evaluated to assess the impact of formulation factors, actuator design, and formulation-actuator interactions on aerosol performance.

Results

Delivered dose (dose exiting the actuator) was not significantly affected by formulation or actuator variants. However, the formulation with lowest API particle size, and highest oleic acid and ethanol content had a statistically significant effect on fine particle dose less the 2µm (FPD<2µm; i.e., dose reaching the deep lungs), causing it to be 1.6-2.2 times higher when compared to the other two formulations, which may be due to the smaller API particle size within this formulation. Regarding actuator design, orifice diameter had a strong effect on the fine particle doses (FPDs, i.e., doses reaching different regions of the lung) for all formulations tested; a decrease in orifice diameter from 0.48 to 0.35 mm increased FPDs between 14-52% and most influential on the formulation containing the lowest API particle size.

Conclusions

Overall, formulation factors and actuator design influenced the in vitro aerosol performance of suspension-based MF MDIs. Results from this work provide insights on how to modulate drug product parameters to achieve the desired in vitro aerosol performance for bioequivalence assessment.