2023 FDA Science Forum

Raman spectrometry as a tool to study minimization of batch age effects and make product quality decisions for biotherapeutic antibody production

- Authors:

- Center:

-

Contributing OfficeCenter for Drug Evaluation and Research

Abstract

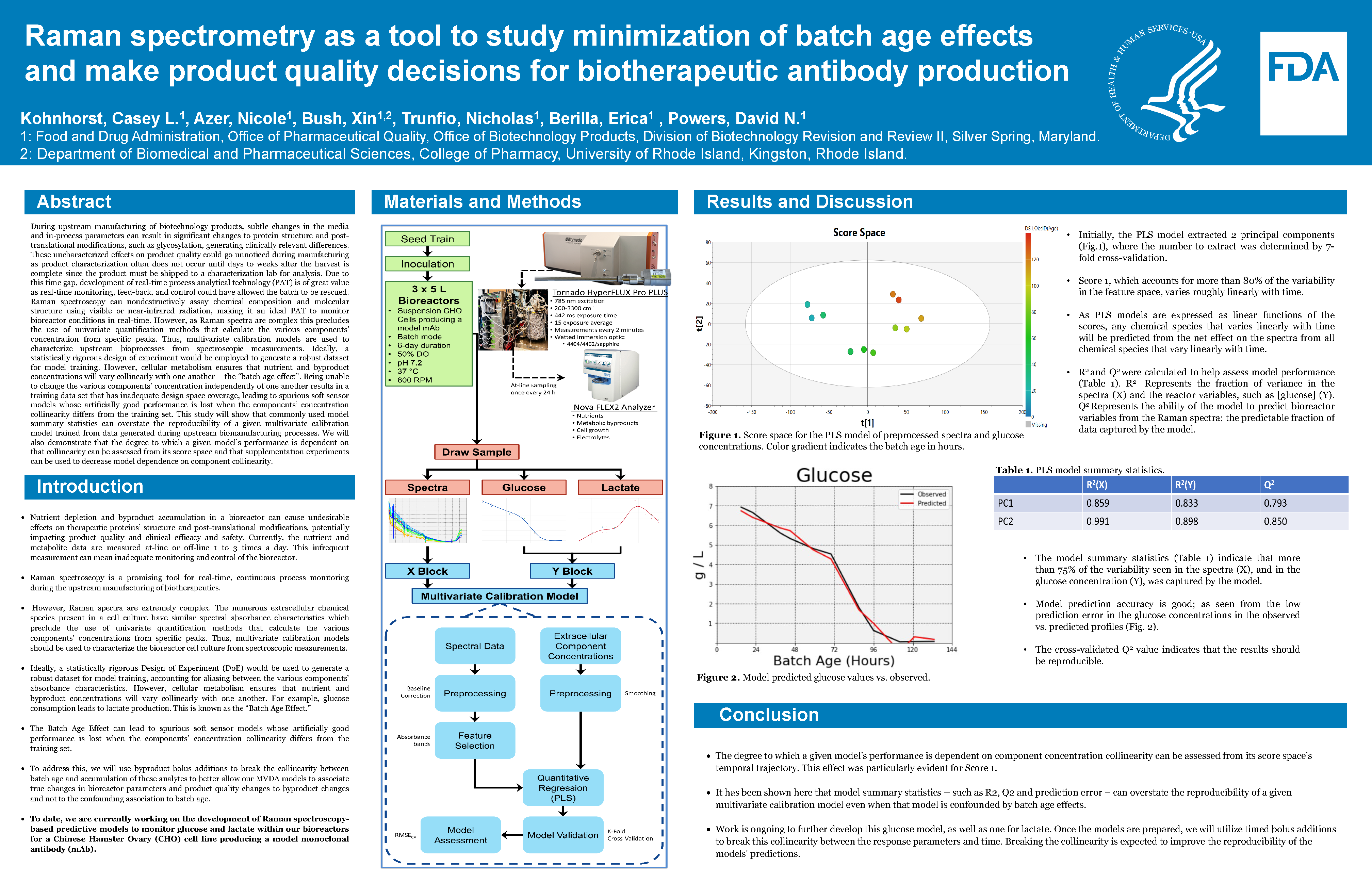

During upstream manufacturing of biotechnology products, subtle changes in the media and in-process parameters can result in significant changes to protein structure and post-translational modifications, such as glycosylation, generating clinically relevant differences. These uncharacterized effects on product quality could go unnoticed during manufacturing as product characterization often does not occur until days to weeks after the harvest is complete since the product must be shipped to a characterization lab for analysis. Due to this time gap, development of real-time process analytical technology (PAT) is of great value as real-time monitoring, feed-back, and control could have allowed the batch to be rescued. Raman spectroscopy can nondestructively assay chemical composition and molecular structure using visible or near-infrared radiation, making it an ideal PAT to monitor bioreactor conditions in real-time. However, as Raman spectra are complex this precludes the use of univariate quantification methods that calculate the various components’ concentration from specific peaks. Thus, multivariate calibration models are used to characterize upstream bioprocesses from spectroscopic measurements. Ideally, a statistically rigorous design of experiment would be employed to generate a robust dataset for model training. However, cellular metabolism ensures that nutrient and byproduct concentrations will vary collinearly with one another – the “batch age effect”. Being unable to change the various components’ concentration independently of one another results in a training data set that has inadequate design space coverage, leading to spurious soft sensor models whose artificially good performance is lost when the components’ concentration collinearity differs from the training set. This study will show that commonly used model summary statistics can overstate the reproducibility of a given multivariate calibration model trained from data generated during upstream biomanufacturing processes. We will also demonstrate that the degree to which a given model’s performance is dependent on that collinearity can be assessed from its score space and that supplementation experiments can be used to decrease model dependence on component collinearity.